Foiling!

Marketing . • December 11, 2019

Learn about the process.

We can talk about the value of adding foil to your print 'til the cows come home, but knowing the process will help understand the possibilities, limitations and worth!

Have you heard of dies?

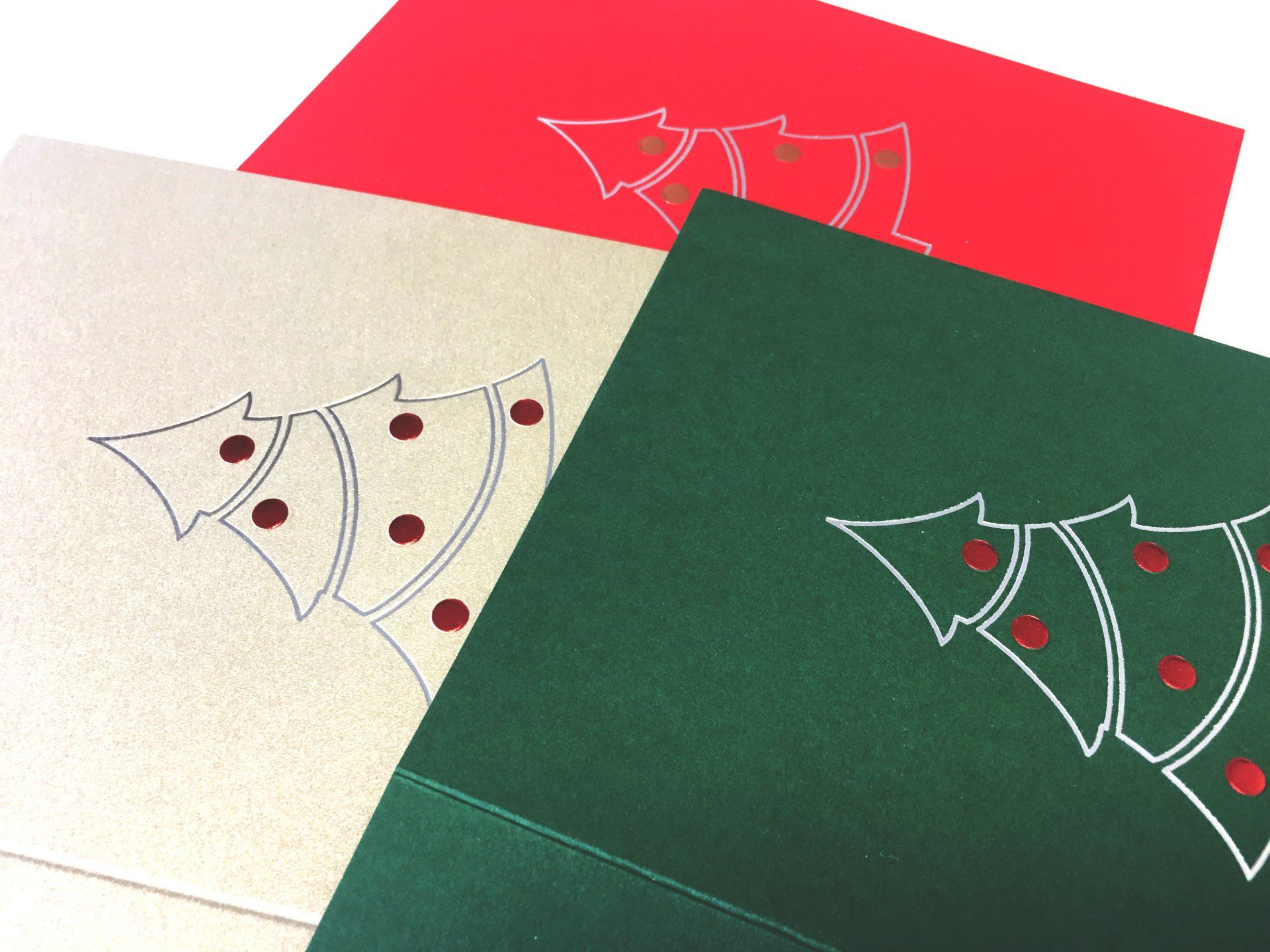

Foiling goes back as far the 5th century, however it doesn't need to be painstakingly done by hand anymore. Using machines has increased precision and speed, allowing a really fine layer of metal foil to be stamped into your design.

In order to do this, a die is required! A die is essentially the metal stamp etched with your design. It's then put onto a hot stamping press and using a whole lot of pressure, applies the foil to your product.

At Love & Humphries we use two different types of dies.

Brass is your top dollar die. It's ideal for multiple uses, it will last a really long time in perfect condition and can be etched with a high level of detail. However, because of this it costs more. This is something worst investing in if you plan on stamping your brand or logo over and over!

The other option is magnesium. This is what we would suggest for a one off print job. It's less expensive, and because of that the die wont hold up as well long term.

The invitations above were printed on Colorplan Fuchsia pink using a magnesium die to apply gold foil.

For any one off print jobs we do our best to reuse at least parts of the dies to reduce waste as much as we can!

Get in touch to see what we can do for you.