Duplexing, Triplexing and Multiplexing. Sound perplexing? It needn't be!

What we're talking about: The bonding together of two, three or even more sheets to create high quality results.

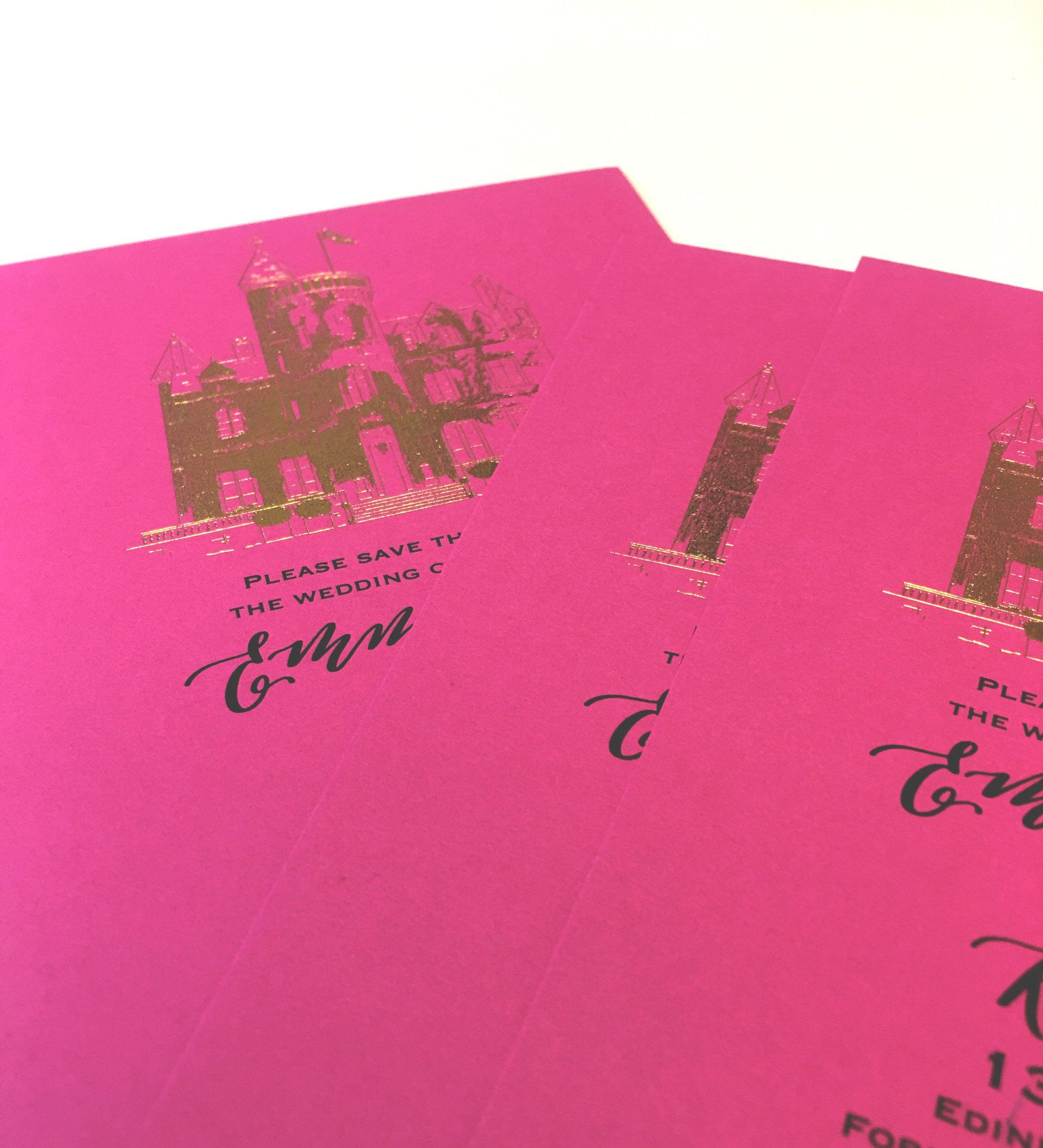

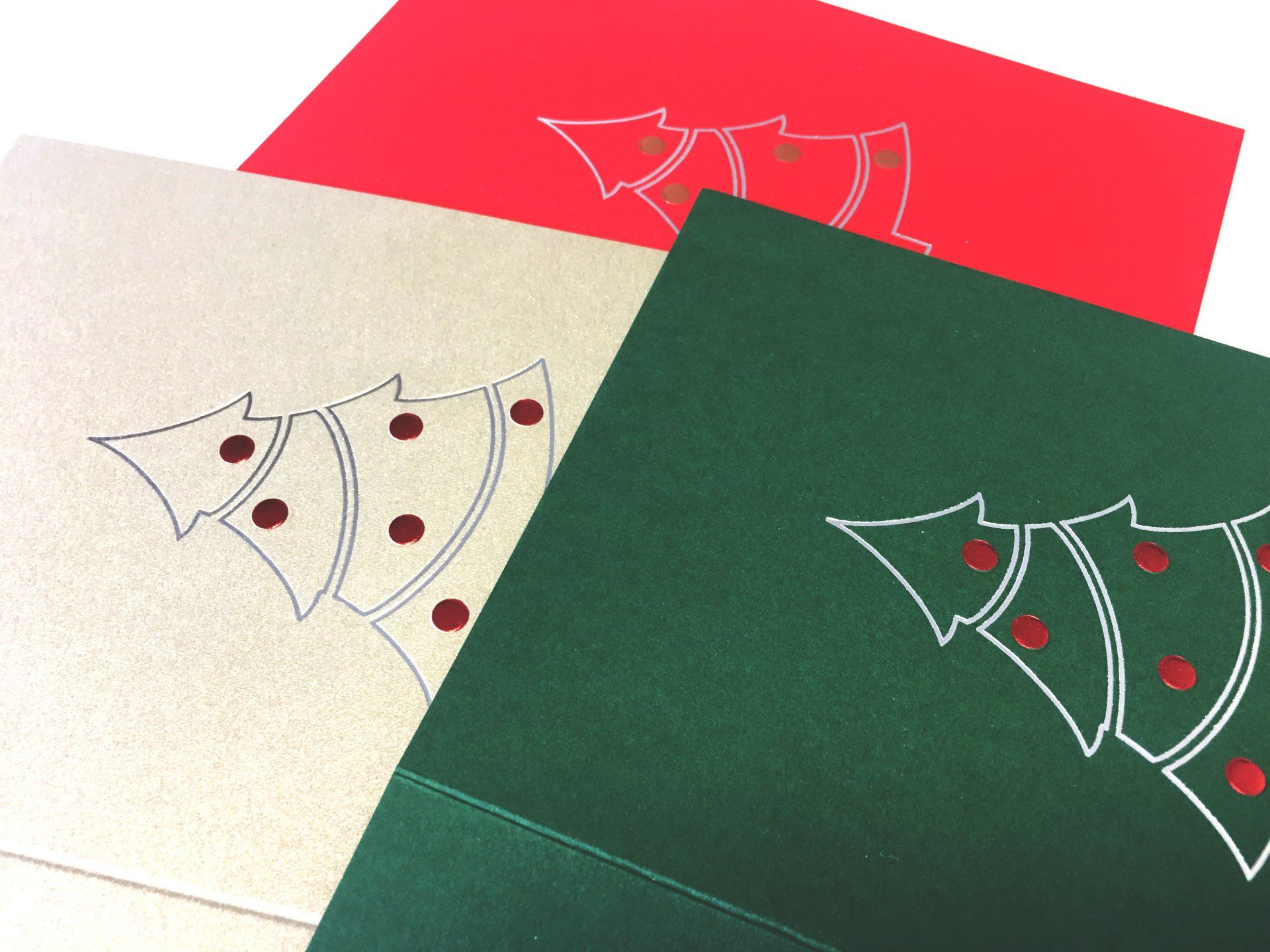

From business cards to invitations and document covers, if you want that extra ‘touch’ of quality then start here!

Take it a step further and combine with foiling, die cutting or laser-cutting e.g. you could die-cut the front board allowing the colour of the second board to show through. The possibilities are endless!

Duplexing – two sheets bonded. The seam is barely visible if the same material is used and this method is great for a thicker quality product. Very popular for two tone business cards.

Triplexing – three sheets bonded. We love using a different colour sheet sandwiched between two sheets to create a nice effect.

Multiplexing

– more than three sheets bonded. Using the above techniques, there may be an occasion for something that requires even more layering and the result will be truly unique. Not very common, so if you want to stand out... Be warned that this can also seem a bit overkill at times!

Side notes:

If combining materials, the weight of each sheet being bonded should evenly balance as to minimise any 'curling' effects as the bonding adhesive drys. Generally speaking, the minimum weight for bonding will be 175gsm and thicker is usually even better.

After the sheets are bonded, it is recommended that they're left 2 to 3 days, this is to minimise any potential curling.